Raymond, Maine (September 7, 2015) – In the south of France, a group of seven international entities is developing the world’s largest tokamak-style (magnetic-torus) experimental fusion reactor, and Dielectric is playing a role. The ITER (International Thermonuclear Experimental Reactor) project brings together the European Union, India, Japan, China, Russia, South Korea and the United States in an effort to harness the physics that power the sun.

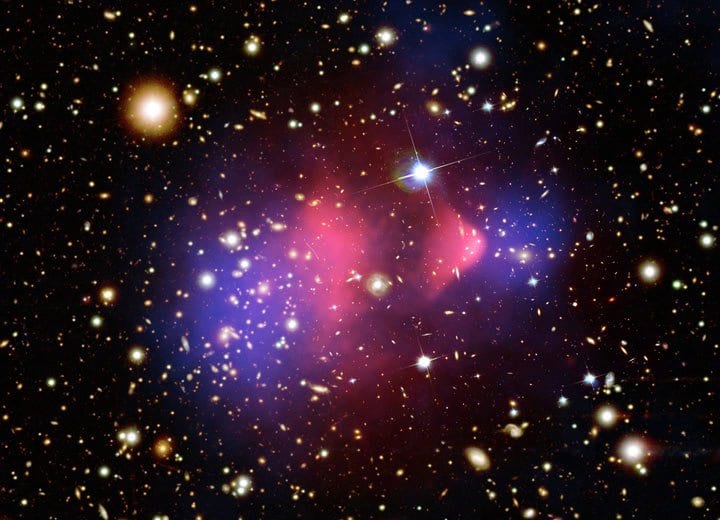

The challenge is unprecedented: create a 500-megawatt demonstration reactor capable of igniting, sustaining and containing for up to eight minutes a reaction that fuses hydrogen isotopes into helium. Temperatures will range from the heat of a stellar furnace to cold that can freeze hydrogen solid. Intense magnetic fields will isolate the super-hot plasma inside the reactor. And staggering levels of energy will be channeled to inject the 50 megawatts of power needed to launch the fusion process.

Over the last few years, US ITER, the project’s American contingent, has relied on Dielectric’s design and prototyping capabilities for a number of essential components. Dielectric partnered with UT–Battelle, manager of the U.S. Department of Energy’s Oak Ridge National Laboratory, where US ITER is based. Collaborating on engineering, design and testing, Dielectric developed 12″ high-power H2O-cooled transmission line and elbows, a high-power gas stop and tuning stub, and 12″ bellows.

Relatively few manufacturers are suited to the rigors of scientific projects such as ITER. The in-depth experience of Dielectric’s engineering staff ensured a deep understanding of the design philosophy required. And previous work with UT–Battelle, MIT, Excelis, and ITT added to Dielectric’s unique qualifications for a project that seeks to build a foundation for a cleaner source of power in the 21st century.